Smart mining system: watch every move of mechanical equipment in the project department in Hunan Province

The mine construction map is 1:1 real, high-definition and dynamically restored, allowing you to experience the construction site

The project leader reported back: "With the smart system, we can see every move of all mechanical equipment very intuitively when we sit in the project department. All construction data is clearly presented, which is very intelligent."

Number of transportation trips-Accurately measure transportation output, efficiency and costs

The accuracy of the number of transportation trips has reached 99.8%. The traditional manual counting method has been transformed into real-time automatic statistics of the number of transportation trips. The accuracy and reliability of the data have been greatly improved, reducing the financial load and effectively reducing management costs.

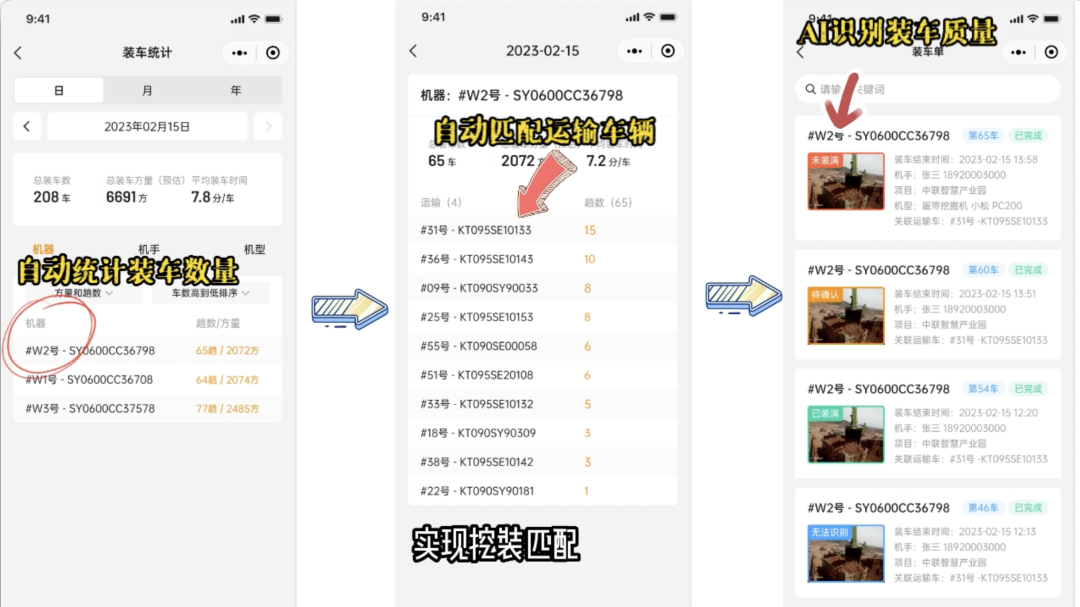

Automatically sum up the loading times, automatically match transportation vehicle to realize the mining and transportation, AI recognize the loading quality.

Watching panel: total loading numbers of the vehicle, average loading time, average loading fuel consumption, total transportation numbers, average transportation time, average transportation fuel consumption. To evaluate the transportation cost by trips of transportation, transportation efficiency.

The system data analyzes the transportation cost, transportation efficiency and profit margin of each vehicle, provides efficient excavation and transportation matching strategies, optimal path planning, makes full use of resources for reasonable scheduling and use, and optimizes inefficient and uneconomical construction methods, realize digital and intelligent management, thereby maximizing economic benefits.

Oil management-Realize full-process supervision of oil consumption

The project's measurement accuracy of refueling reaches over 98%. It achieves real-time sensing of equipment oil level changes by fuel sensor, comprehensive control of the machinery's refueling data and fuel consumption data, and timely alarm reminders when there are abnormalities, ensuring the authenticity and reliability of the refueling data and fuel consumption data, and preventing theft, thereby reducing losses and risks. In addition, it also reduces fuel waste caused by improper operation, thereby improving fuel utilization and helping the project save costs.

Fuel chart by the platform

Working hours statistics-Accurate statistics on the working status of machinery

Machinery State understands the working conditions of machinery in real time. Reasonably arrange machinery usage time based on working hours data to avoid unnecessary shutdowns and idling, and improve work efficiency and resource utilization.

real-time positioning-Real-time monitoring of project construction by cameras and wireless transmission

The current position and running trajectory of the machine can be grasped in real time to ensure that the machine is working within the predetermined area, and abnormal situations can be detected in a timely manner, such as when the machine leaves the working area, abnormal residence time, etc., and can be promptly reminded. Wherever the mechanical equipment is working and how much work it is doing, it is well documented, thereby strengthening the safety management of the machinery and reducing the risk of machinery being stolen or abused. The system accurately monitors the working conditions of the mechanical equipment, including what time it starts every day. Start, stop time, idle time, working hours, fuel consumption, number of transportation and other data no longer rely on manual management, providing data support for project management and improving management efficiency.

Monitoring screen, in the platform monitoring the real time working hours, fuel consumption, video surveillance, etc.

Data screen, very easily to know the situation of the construction site working situation.

Statistical reports-Intelligent report data to improve management efficiency

The system provides rich business data reports, comprehensive analysis of machinery working hours and fuel consumption, and intelligent evaluation. Problem machinery can be seen at a glance, reducing labor management costs. Timely discovery of problems and anomalies in the business through report data provides an objective and reliable basis for intelligent equipment management and settlement, changing the past situation of relying on manual verification of large amounts of paper data.

Through this surveillance system, whether it is equipment management, output efficiency, or safety control, we have received comprehensive, accurate, and real-time data support and management decision-making support.